A completely different, environment-centred approach that was designed especially for the purpose of protecting the environment. The process uses plasma instead of chemicals to modify the surface of wool fibres to make them machine washable. It is the first real ecological alternative with the potential to replace the current chemical-based industry standard. It has been developed over the course of 10 years specifically to reduce the need for chemicals in the production process.

A plasma field is generated by discharging a voltage between two electrodes in a special machine. Carefully prepared wool passes through the plasma field where electrons and ions in the plasma interact with the wool fibre. They alter the friction profile of the fibre surface, removing the normal felting effect of untreated wool. The wool is then spun into a thread that can be used for knitting or weaving.

Plasma is a different state of matter (like a liquid, solid or gas) where a gas has been energized at fundamental level by the input of heat or electricity. Gas atoms are ionized within the plasma and electrons are freed up transforming the gas into a more reactive state. Plasma occurs naturally in the sun, in lighting strikes and in the aurora. Artificial plasma is harnessed in fluorescent bulbs, flat screen TVs and in industrial applications, such as applying coatings.

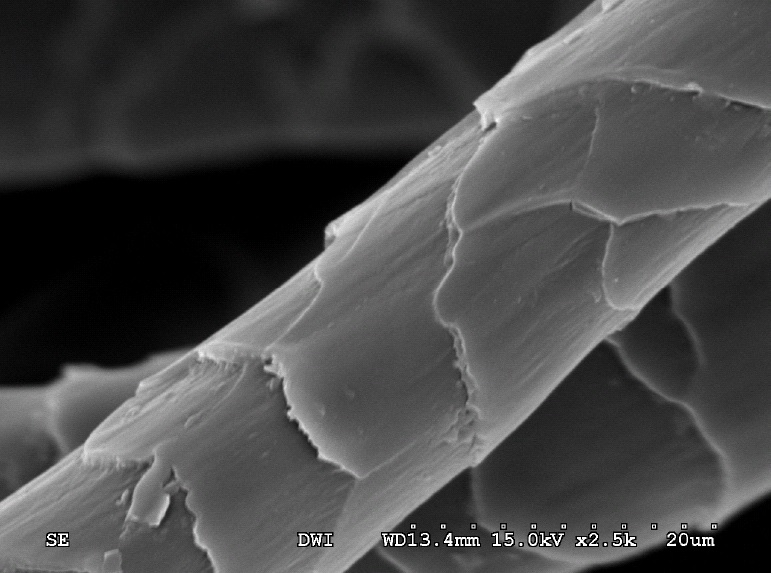

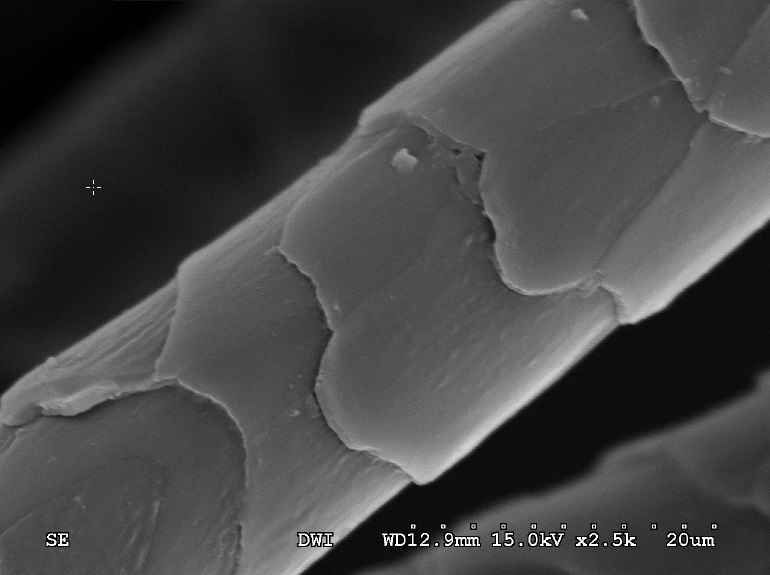

Wool has scales on the surface of the individual fibres that are grown in one direction. When untreated wool fabrics are washed, the heat and water allows these fibres to move. The scales allow fibres to move in one direction, but catch on each other to prevent them moving back creating a ratcheting effect that leads to felted, matted, and shrunken wool fabrics.

The traditional industrial treatment burns the scales to reduce their prominence and then adds a resin to partially coat the fibre, meaning the fibres can move freely in both directions and do not get caught on each other.

Naturetexx Plasma works differently. The exposure of the fibres to carefully calibrated - both in intensity and duration - plasma field oxidises the surface and creates tiny nano-scale holes in the surface of the fibre. These holes increase the surface friction of the whole fibre, without damaging the scales. This added friction stops the fibres from really moving at all, avoiding the ratcheting effect that leads to felting and shrinkage.

The graphic below shows the lack of damage to the fibre after treatment.

The oxidated surface and nano-holes created by the treatment allow moisture to penetrate the normally water-repelling fibre Surface giving Naturetexx Plasma treated fabrics the ability to absorb moisture much faster than untreated or traditionally treated wool.

Because the wool fibre remains largely intact, aside from absorbing moisture, the properties of the fibre - including strength and abrasion resistance - remain very similar to untreated fibres.